Home-News-aluminium strip-Longitudinal cracks in aluminium checker plate sheet

Longitudinal cracks in aluminium checker plate sheet

Hits: 16170 • Add time2019-07-31 17:53:58, author:Haomei Aluminum Plate

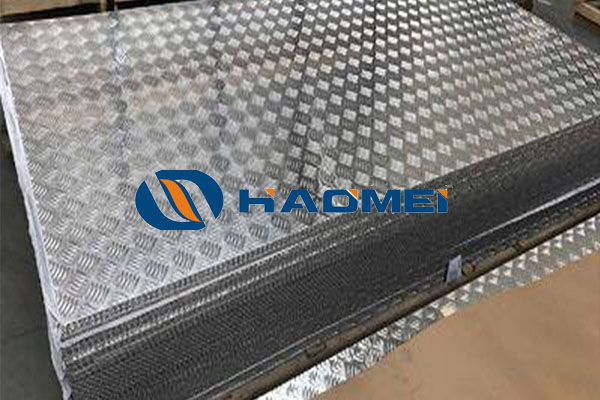

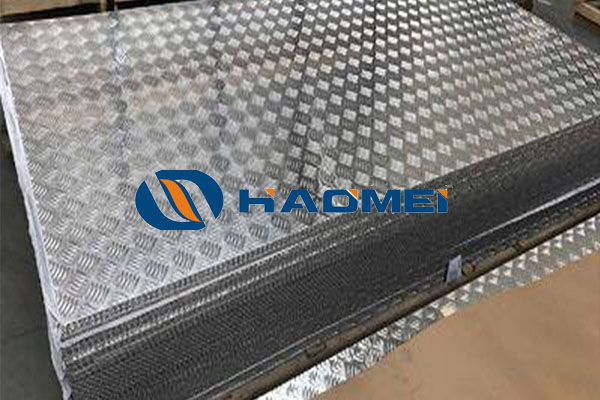

The aluminium checker plate sheet tends to have some defects in further processing, such as longitudinal cracks, lateral cracks, easy shrinkage, dead zone shearing and folding, curved aluminum plate processing parts bending, shrinkage caused by the wrong cross-sectional size, excessive residual stress, coarse crystal rings and so on. Effective measures to prevent longitudinal cracks from coming into being are as below.

The most effective way is to improve the lubrication and temperature and then control the mold. It is also possible to use a concave die with a taper angle. The taper angle acts to make the force have a component in the direction parallel to the tapered surface. The component is opposite to the direction of the friction, thereby facilitating deformation and flow of the

aluminum sheet. According to different conditions, a suitable cone angle can be determined by calculation to offset the influence of friction.

In processing an aluminum veneer into an

aluminium checker plate sheet, a difficult deformation zone often forms at the bottom of the die, which we generally call "dead zone". Since the aluminum plate metal in this area is not deformed, and the upper metal adjacent to it is deformed and flows, strong shear deformation occurs at the junction, and in severe cases, metal shearing, that is, "dead zone" crack, sometimes due to the upper part The large flow of metal flows with the "dead zone" metal to form a fold. Therefore, when the deformed

aluminum plate passes through the orifice portion, the surface metal flows slowly due to the influence of friction, and the axial portion flows quickly, so that the uneven deformation formed in the cylinder is further intensified, and the inner and outer aluminium metal flows. There are differences in speed, but the two are a whole, so there must be a balance of internal forces, which increases the value of the additional tensile stress.

Tagged:aluminium checker plate sheet, aluminium checker plate, aluminium checker sheet